Services

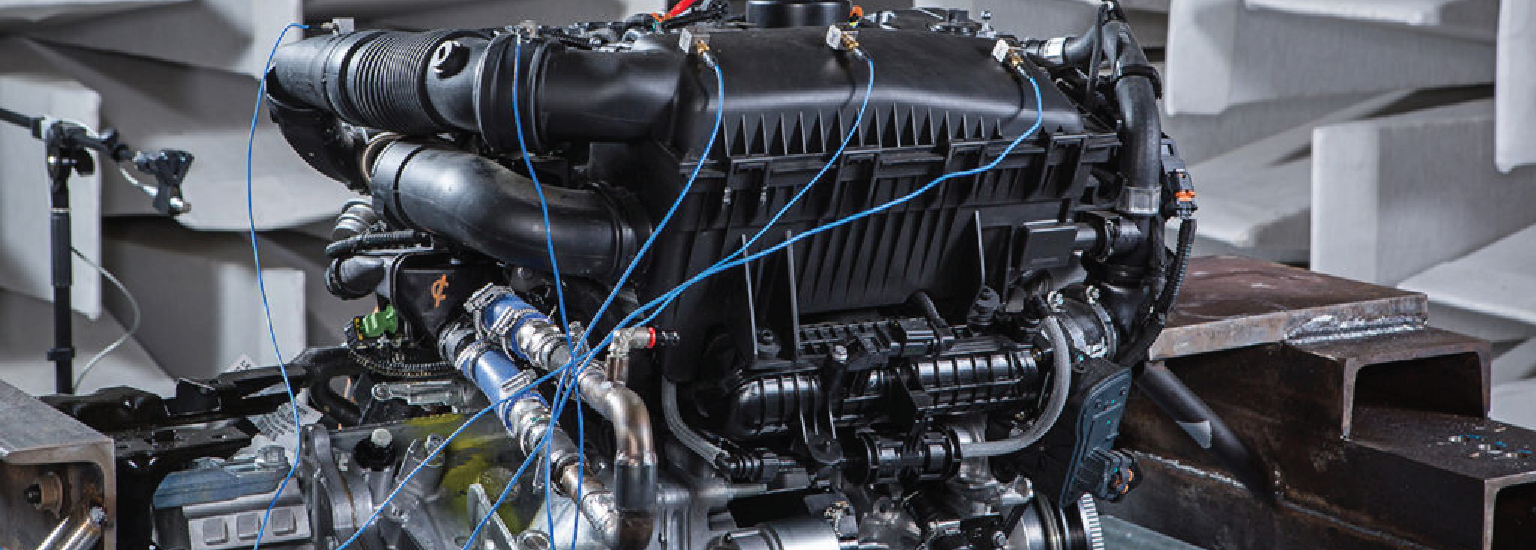

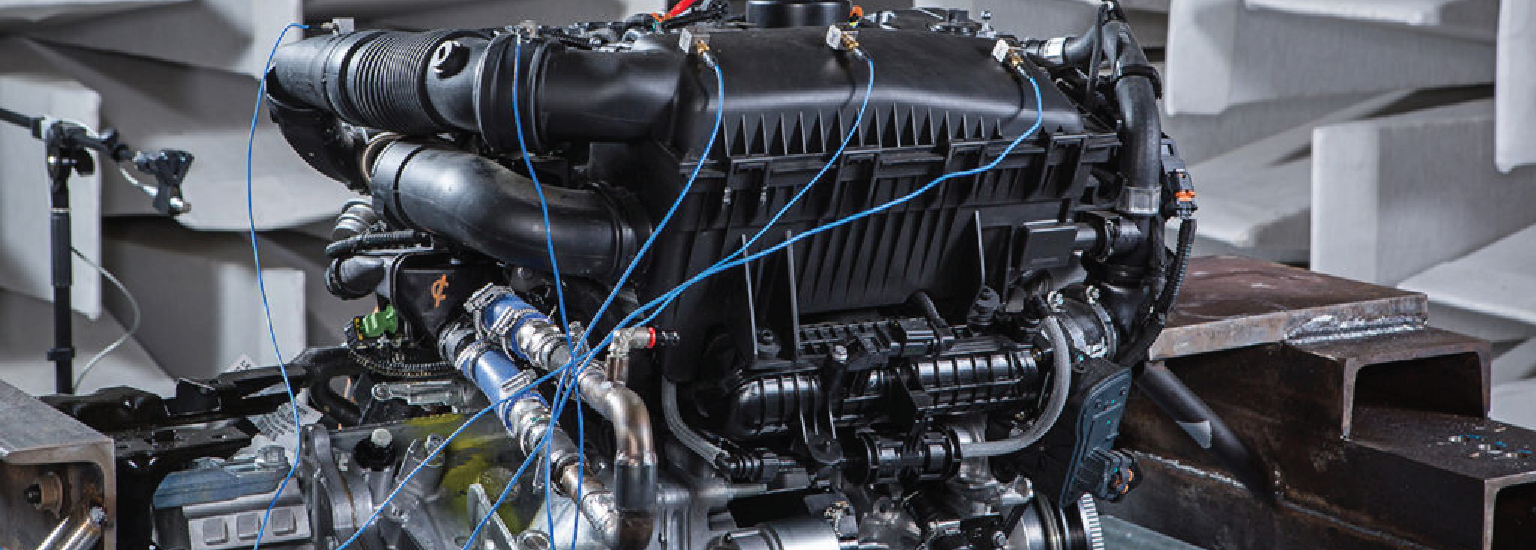

Vibration & NVH

Dynamics-driven design validation to reduce resonance risk, improve durability and meet noise/vibration targets. We focus on realistic excitations, clear modal interpretation and actionable countermeasures.

Services

Dynamics-driven design validation to reduce resonance risk, improve durability and meet noise/vibration targets. We focus on realistic excitations, clear modal interpretation and actionable countermeasures.

Overview

Identify mode shapes, participation and resonance proximity to operating orders.

Predict steady-state vibration levels under rotating machinery excitations and order content.

Shock/impact events, startups, step loads and time-domain scenarios.

Rubber mounts, stiffness tuning, coupling to base-frame and interface management.

Identify top risks (resonance, fatigue hot-spots, amplification paths) and prioritize actions.

Frequency targets, countermeasures, and a sign-off package with traceable assumptions.

Capabilities

Deliverables

Assumptions, boundary conditions, excitations, damping approach, results and recommendations.

Key modes, resonance proximity, participation ranking and “what to fix first” list.

Stiffness/damping/tuning recommendations with expected frequency shifts and response reduction.

Workflow

RPM range, orders/harmonics, excitation sources, target locations and acceptance criteria.

Interfaces, mount stiffness, mass distribution and realistic constraints (not “over-fixed”).

Convergence checks, sensitivity review (mount stiffness/damping), and sanity checks vs expected physics.

Frequency targets, mitigation options and a practical action list with quantified benefit.

Share the RPM range and mounting concept — we will respond with scope, timeline and deliverables.