Services

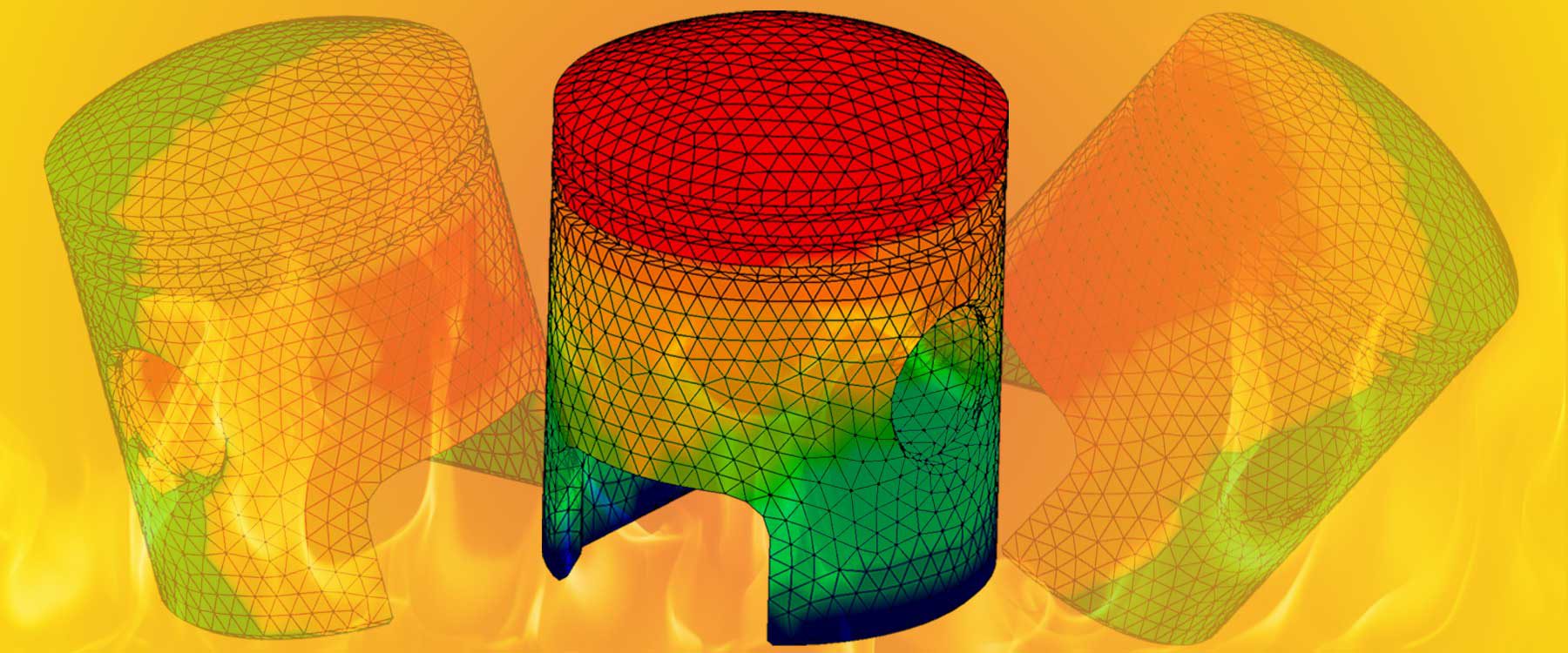

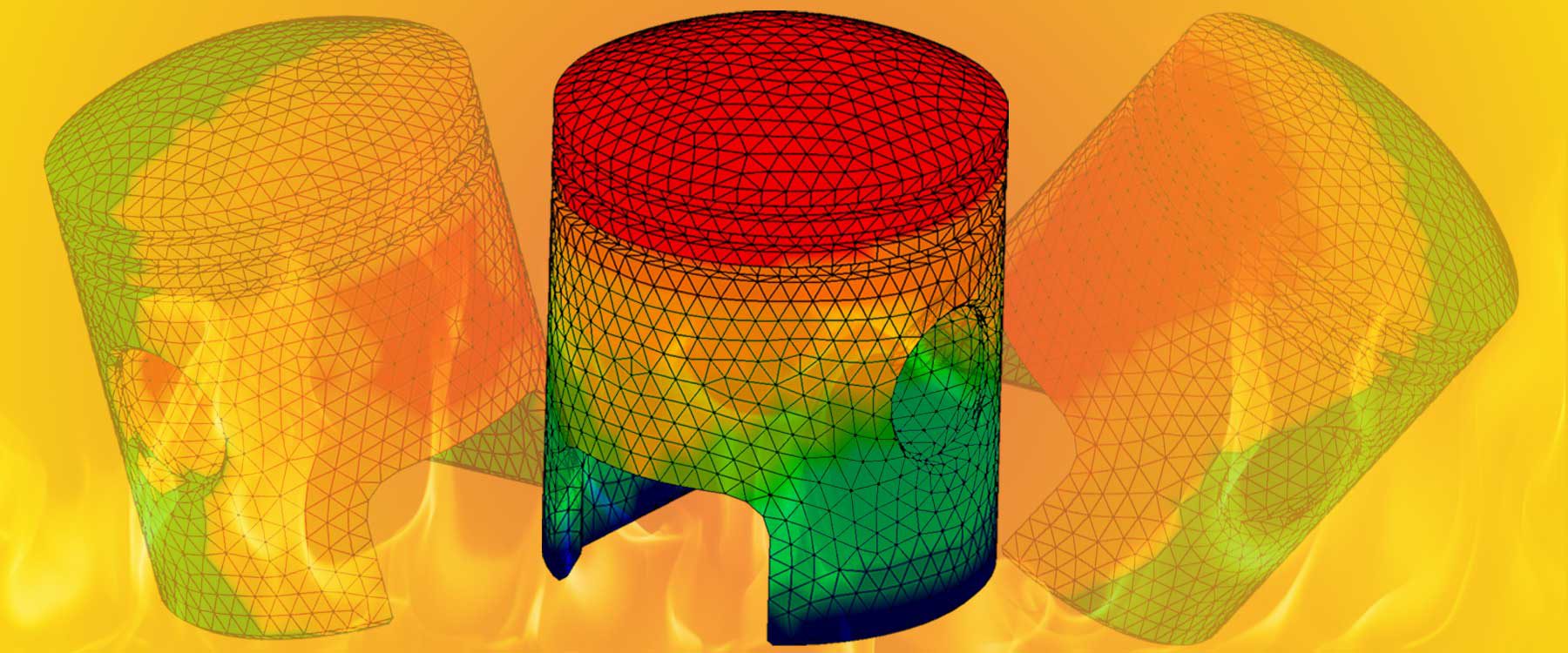

Thermal Analysis

Temperature margin validation and hotspot risk reduction for reliable designs. We focus on realistic heat loads, boundary conditions, and decision-grade results.

Services

Temperature margin validation and hotspot risk reduction for reliable designs. We focus on realistic heat loads, boundary conditions, and decision-grade results.

Overview

Baseline temperature fields, thermal resistance paths, and operating equilibrium.

Warm-up, cooldown, step loads and duty cycles — time-dependent risks.

Critical locations, gradients and temperature-sensitive components.

Provide temperature fields and gradients for structural / fatigue assessment where required.

Validate heat sinks, airflow assumptions, interfaces and insulation strategies.

Assumptions → loads → BCs → results → margins → engineering recommendations.

Capabilities

Deliverables

Heat loads, BCs, assumptions, model setup, temperature results, margins and recommendations.

Component temperature limits, achieved margins, critical points and design sensitivities.

Ranked mitigation options (interfaces, insulation, cooling paths) with expected benefit.

Workflow

Heat sources, operating points, ambient conditions and component temperature limits.

Convection assumptions, radiation relevance, interface resistances and simplifications documented.

Sensitivity checks (BCs / contact / loads) to confirm conclusions are robust.

Margin summaries, hotspot mitigation proposals and a clear sign-off recommendation.

Share operating points and constraints — we will respond with scope, timeline and deliverables.