A STOP analysis is a multidiscipline analysis, consisting of Structural, Thermal, and Optical Performance analyses, that is performed for all space flight instruments and satellites.

This course will explain the different parts of performing this analysis. The student will learn how to effectively interact with each discipline in order to accurately obtain the system analysis results.

• Purpose

• General Information

• Analysis Cycle

• Levels of Analysis Fidelity

• Data Transfer

• Model Checks

• Thermal Modeling

• Structural Modeling

• Optical Modeling

• Best Practices

• Additional Things to Consider

• Summary

STOP analysis estimates the thermally-induced performance degradation of an optical system

– Possible objectives

• Create or verify system engineering budget allocation for given thermal loading

• Stress/Deflection responses to address load capability of the structure

• Final performance estimate for programs with incomplete ground testing, such as JWST – – Typical quantities predicted

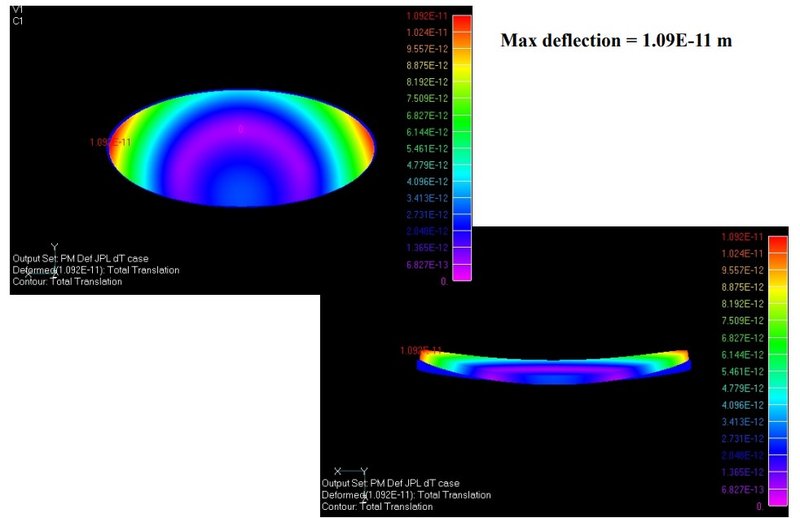

• Mirror surface distortion

• Structure distortion and stress

• System wavefront and pointing error due to optics motions (rigid-body)

– Cyclical in nature and applied at various phases during the design cycle with various levels of model maturity

A complete and thorough analysis requires expertise in 3 disciplines

• Thermal design/analysis

• Structural design/analysis

• Optical design/analysis

Team needs to work together!!!

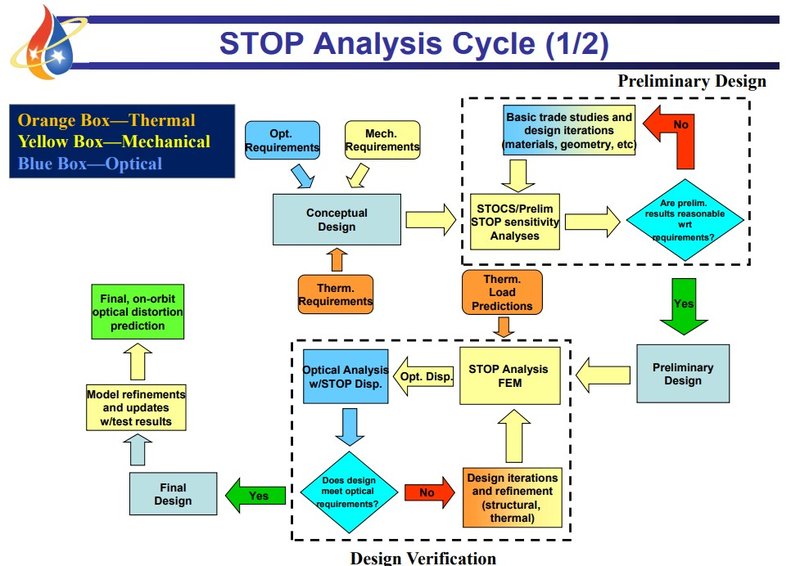

Basic Data Flow (see next chart)

– * Thermal model creates temperature set(s)

– * Temperatures are applied to structural model

– Distortion or motion of key optics calculated in structural model

– Distortions or motions applied to optical model

– Optical figure of merit calculated

Key kickoff STOP team meeting agenda items (generally organized by mechanical lead):

– Determine optics sensitive to motion

– * Thermal environments in which data may be taken

– * A common coordinate systems, origin, and units for all 3 models

– * Data transfer methods between disciplines (see later chart)

Conceptual

– STOCS (structural/thermal/optical shifts) analysis

• Assumes stress free mounting of components and uniform gradients and bulk temps.

• Used sometimes in initial evaluation of a design

• Structural modeling may be relatively simplified at this stage

Preliminary Design

– Primary structure modeled with simplified secondary structure (and possibly optics)

– Captures load paths more accurately than STOCS and used to more accurately predicts optics motion

– Initially used with artificial load cases for sensitivity analysis, but may be refined with more detailed thermal mapping

– Material trade studies often performed

Design Verification

– Detailed model with all optics and mounts modeled.

– On-orbit temperatures (and possibly test configurations) modeled with optics motions mapped back to optical analysis for full analysis cycle.

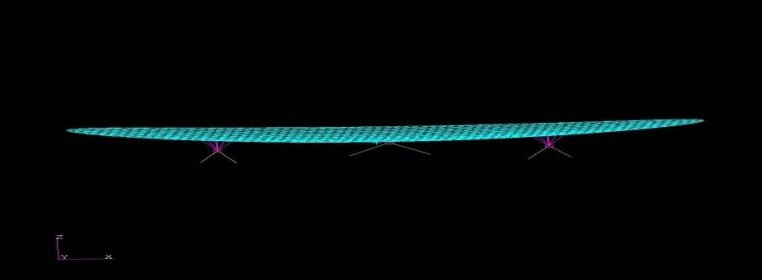

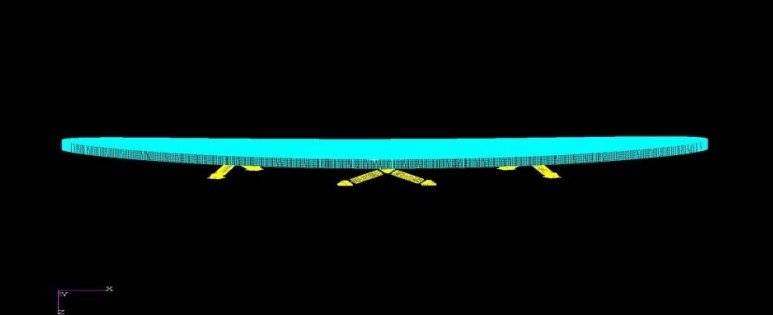

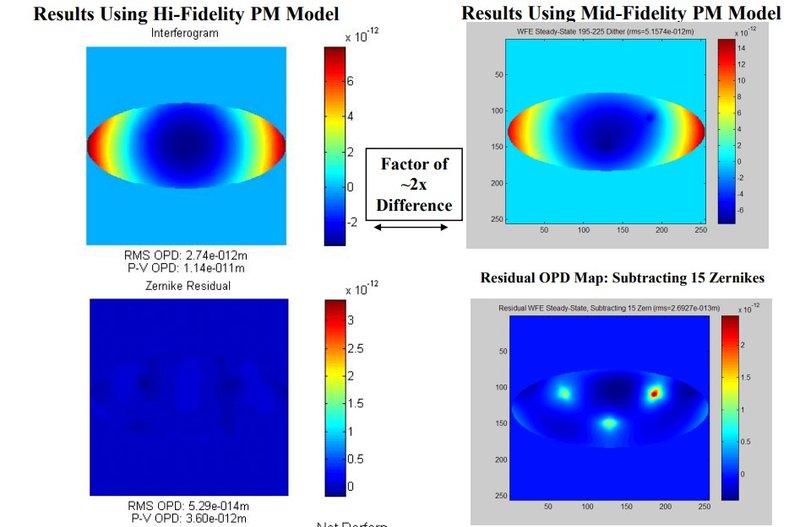

Conceptual Design

– PM Low-Fidelity Structural Model

– Description: Flat plate model to represent PM and bar elements to represent mounts

– Purpose: Simple sensitivity (bulk and gradients) and trade studies

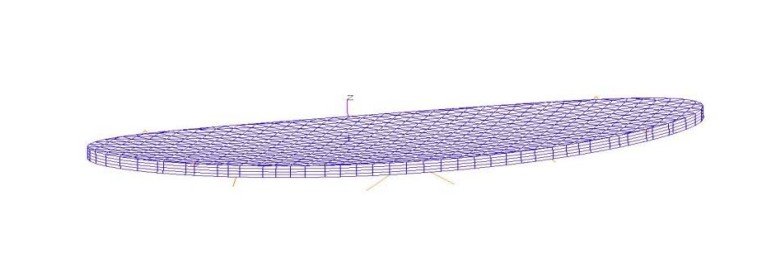

Preliminary Design

– PM Mid-Fidelity Structural Model

– Description: Solid model to represent PM and bar and spring elements to represent mounts

– Purpose: Mapping with preliminary temperatures and material trade studies

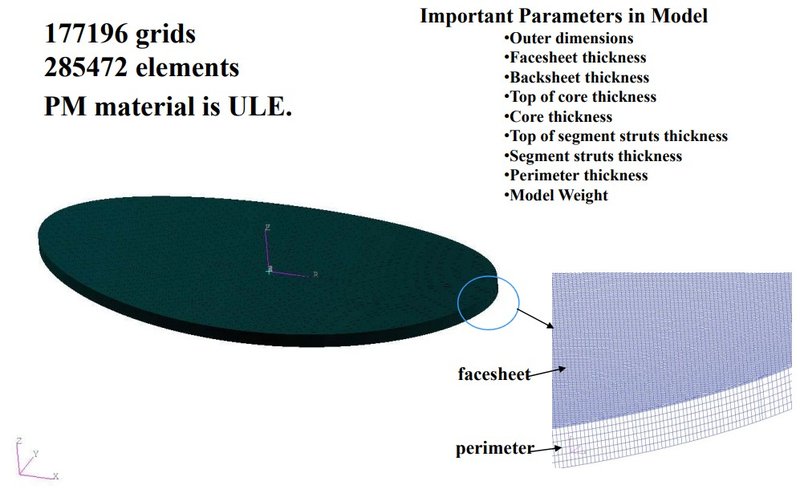

Design Verification

– PM High-Fidelity Structural Model

– Description: Detailed plate model that represents all core and mirror segment geometry and detailed bar and solid elements to represent the mounts

– Purpose: Detailed temperatures mapped to predict final optical performance

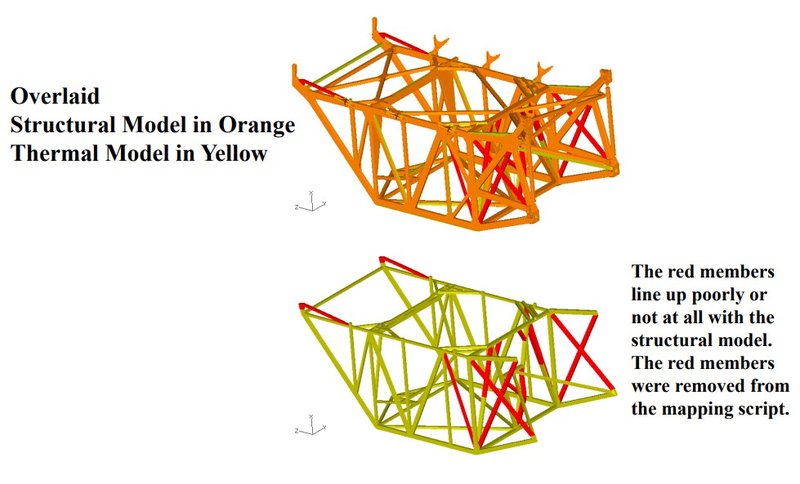

Data transfer between disciplines is always challenging!

Thermal-to-structural data flows:

– Thermal calculates T using TMG, outputs text files with node ID, [X,Y, Z,] and T. Structures uses MATLAB to read and map this data to the nearest NASTRAN grids. Requires extensive manual mapping adjustment (being used for JWST)

– Same model geometry used for both the structural model and thermal model. Mapping performed internal to TMG! The difficulty is agreeing on a common model geometry, like blanketing (used for TPF).

– Thermal engineer accepts a similar (but not identical) structural model and mapped temperatures using Thermal Desktop (used for TIRS, ATLAS).

Structural to Optical data flows:

– Optics provides sensitivities in Matlab to structures. They are scaled by calculated optical motions to approximate performance. Checked with ray traces (being used for JWST)

– Deformations provided in an Excel spreadsheet and applied by scripting in ZEMAX optical analysis program (was used for IRMOS)

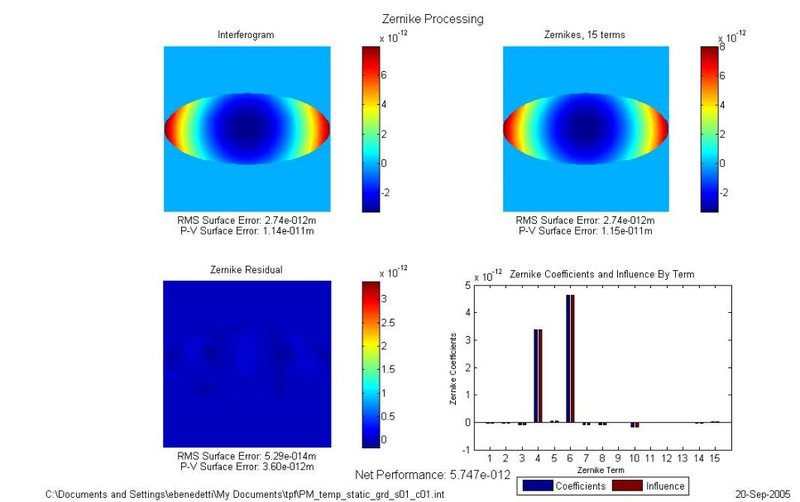

– SIGFIT transformed NASTRAN punch file data into interferograms. These were added to optical model by a MATLAB routine created by the Optics engineer. Output is optical performance. (was used for TPF)

• Note, SIGFIT has recently been updated so it can take NASTRAN data and convert it directed to optical data without having to use a MATLAB routine.

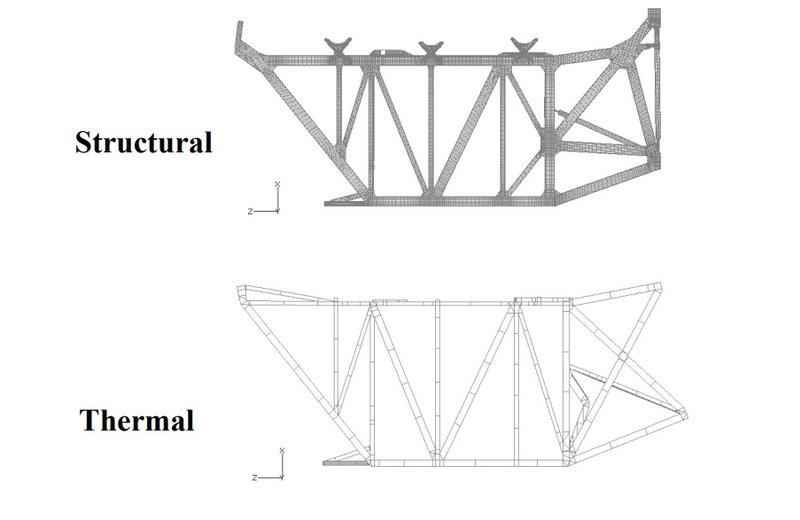

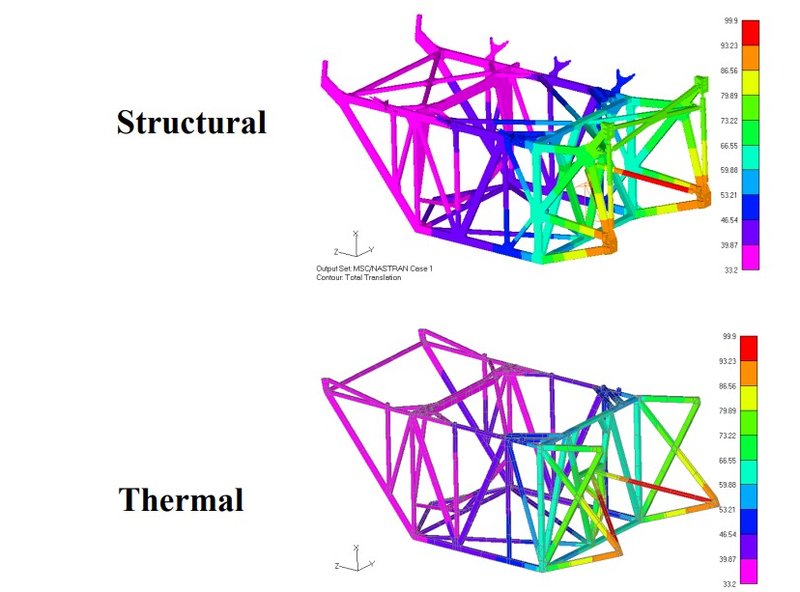

Thermal to Structural

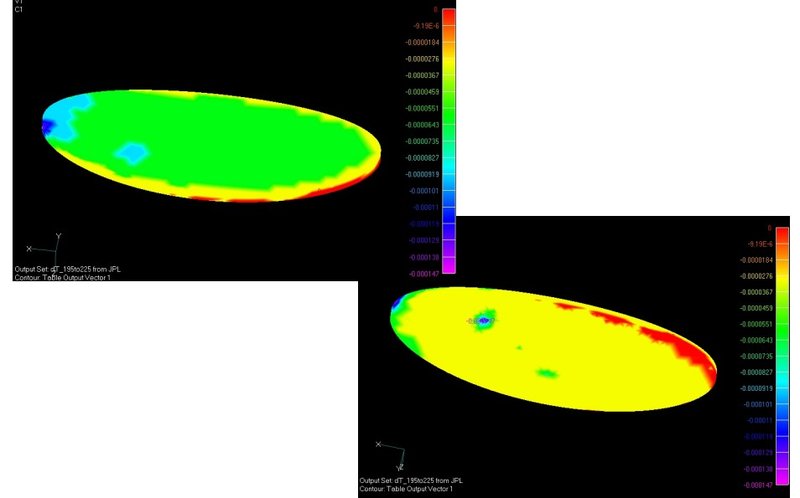

– Geometric comparison between Thermal and Structural Models

– Temperature comparison between Thermal and Structural Models

Structural to Optical

– Optical results (WFE) comparison between Structural Model prediction and Optical Model to a known values

– Final check with computed results between simplified optical representation and full optical analysis program

Final result: provide thermal model nodal temperatures due to all critical events to structural engineer

Thermal model

– Thermal engineer can use any program to develop thermal model and calculate temperatures, such as TMG, TSS and SINDA, FEMAP, PATRAN, Thermal Desktop, etc.

• JWST using TMG but most other projects using Thermal Desktop

– Discussion with structural engineer as to the format of the temperatures

• Temperature mapping can be performed by Thermal Engineer or Structural Engineer

• TMG or Thermal Desktop works well for mapping especially if corner node method is used.

• Blanketing---how will that be handled?

– Discussion with structural engineer as to the thermal cases to be analyzed (iterations often required after initial optical results)

• Hot Case

• Cold Case

• Worst gradients

Data flow checks to be performed

– Provide temperature case used for initial mapping

– Compare temperatures from thermal analysis with structural model temperatures

• Meet all modeling guidelines and analysis checks

Final Result: Provide deformation or motion of optical elements and other critical components to optical engineer.

Structural Model

– Structural engineer can use any program to perform structural analysis

• NASTRAN dominates @ GSFC but any FEM code could be used

• Create and manipulate models with PATRAN, FEMAP, etc.

– Establish format of the temperatures with thermal engineer

– Establish format of the deformation with optical engineer

– Can also develop initial optics results utilizing a LOM or MATLAB script provided by the optical engineer (this helps with many thermal load case iterations that are often needed) • Data flow checks to be performed

– Compare temperatures from thermal analysis with structural model temperatures

– Simple deformation cases used to check optical analysis and data flow

Meet all modeling guidelines and analysis checks

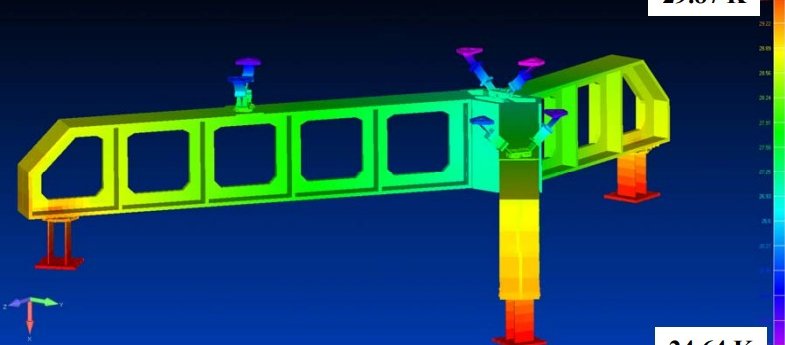

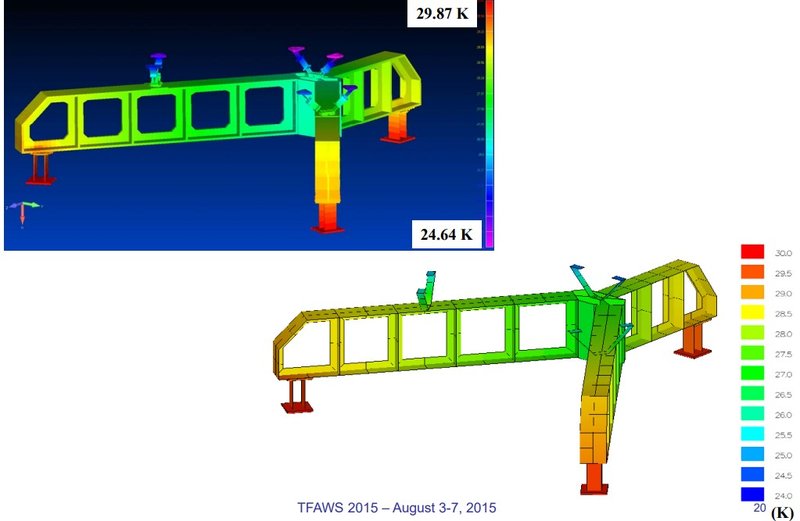

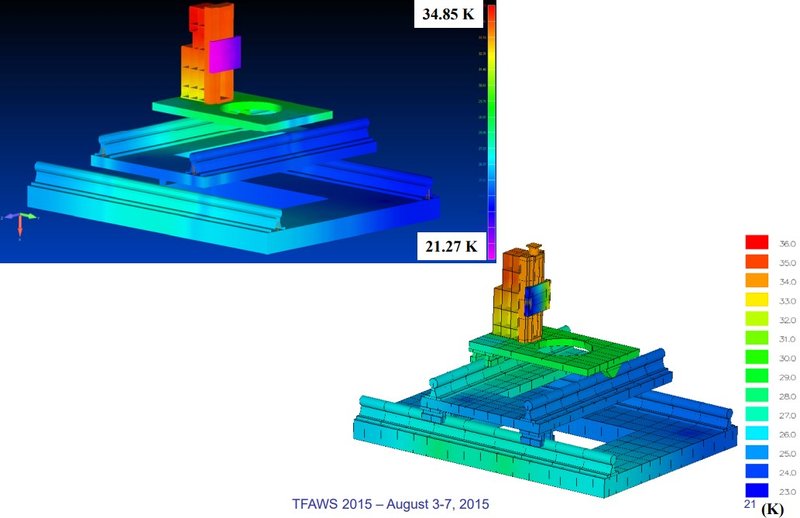

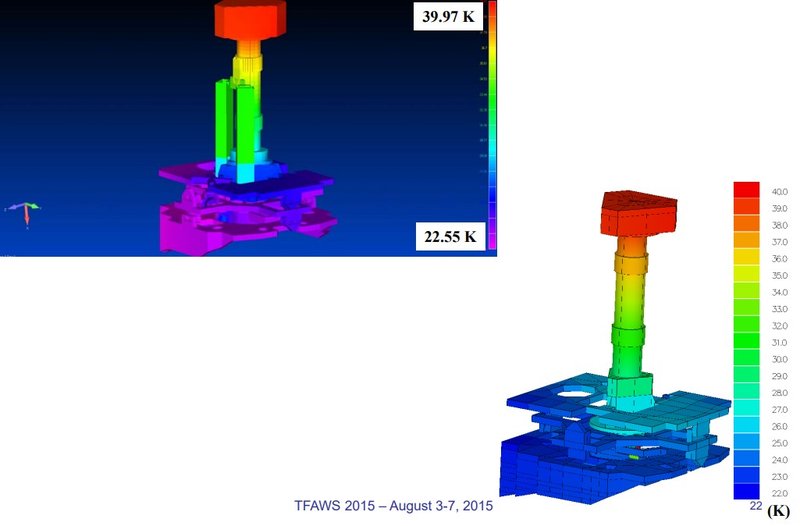

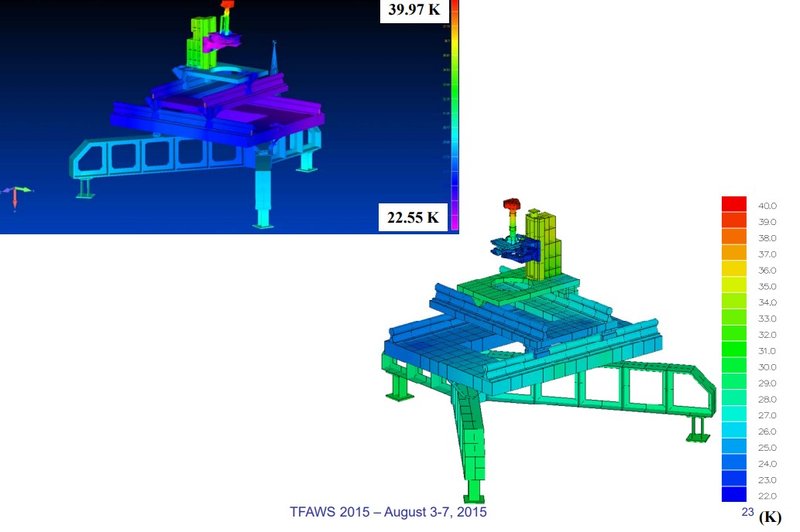

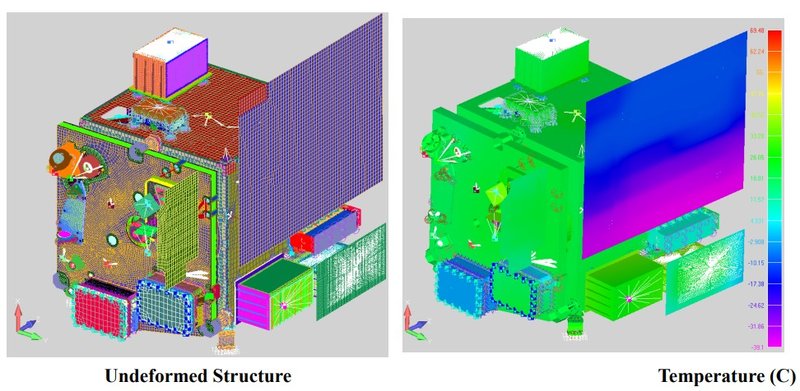

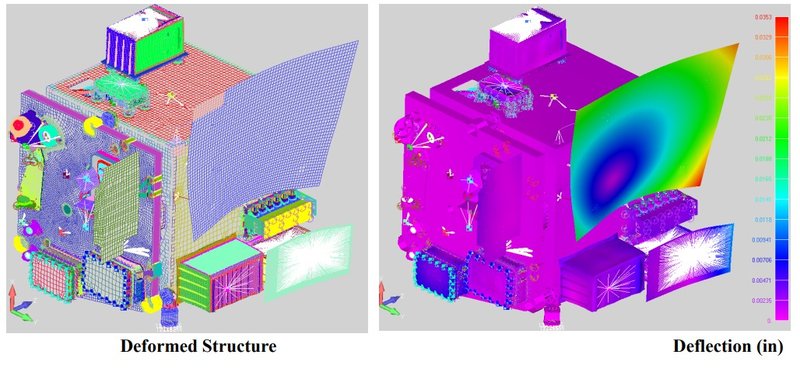

STOP analysis models often are very detailed and time consuming to solve

So, many instances, the assembly will be broken up into components to perform structural/thermal mapping of that component

The mapped components are then combined to run the assembly model.

See the following example performed for the JWST ISIM Beam Image Analyzer.

Final result: Key figure of merit compared with optical requirements. Will the system work?

Optical Model

– Optical engineer can use any program to model optical performance, such as Code V, ZEMAX, etc.

– Discussions with structural engineer as to the format of the deformation for optical analysis

Data flow checks to be performed

– Simple deformation cases used to check optical analysis and data flow

Meet all modeling guidelines and analysis checks

Early coordination among thermal, structural and optical engineers BEFORE modeling begins will streamline the process.

Test and validate data transfer methods between engineering disciplines

– How will temps be mapped to structural model?

– Verify that structural displacements of optics are in the correct format for optical analysis (coord system, units, etc).

– Perform sample “dry runs” of data transfer before tackling actual model results

Don’t wait until the full-up, detailed model is complete before test verifying model results

– Component level testing can be very useful, since much of the optical error can occur at that level rather than at the full, optical bench level

It’s important to make sure all three disciplines (structural, thermal, and optical) are involved in the STOP analysis

– Shortcuts in any one disciplines can reduce confidence in results and make identifying sources of results error that much harder.

When used most effectively, STOP analysis is an iterative process performed at multiple stages of the design process.

– Initially should be considered part of the design process

The greater the number of interfaces in the structure, the greater the possibility of introducing error.

– Can become increasing complicated if components and substructures are coming in from different sources to be integrated with the full-up system model

This is truly multi-disciplinary analysis process and needs the contributions of all three disciplines.

TOP analysis is an integrated, multidiscipline system analysis which predicts performance of an optical system due to variations in temperature.

STOP analysis requires involvement from thermal, structural and optical engineering design and analysis.

Communication between team members throughout the entire process is key in completing an accurate, comprehensive STOP analysis!